Optimize Your

Inspections with Harpia

- Dive into a world of possibilities where traditional Inspection Processes meets modern solutions.

Explore AI-Image Processing Solutions and Operated By Cutting-edge Technologies.

Our Solutions

Harpia

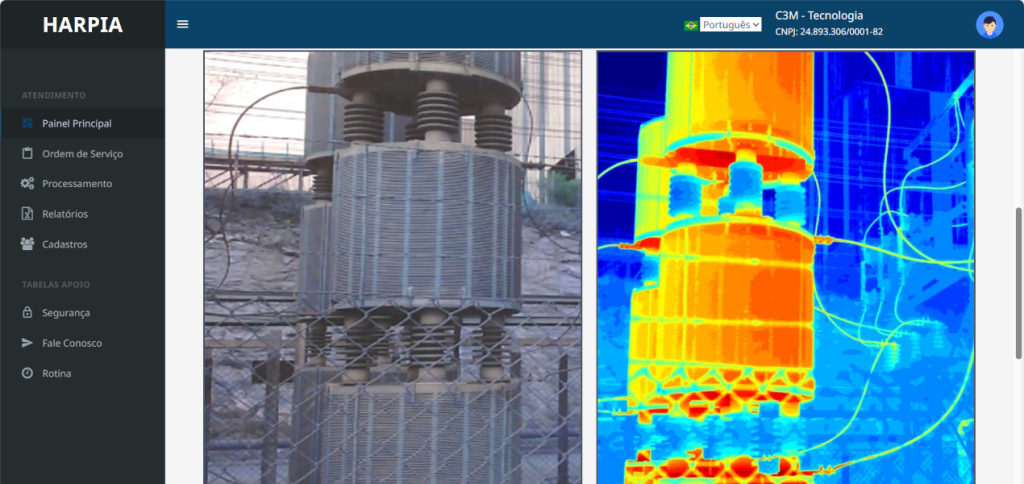

Inspection with AI-Powered Image Analysis

Our system employs cutting-edge artificial intelligence to meticulously analyze visual data for equipment and infrastructure. This enables a wide range of inspection applications, including corrosion detection and infrared analysis.

Some clients we’ve worked with

What is Harpia?

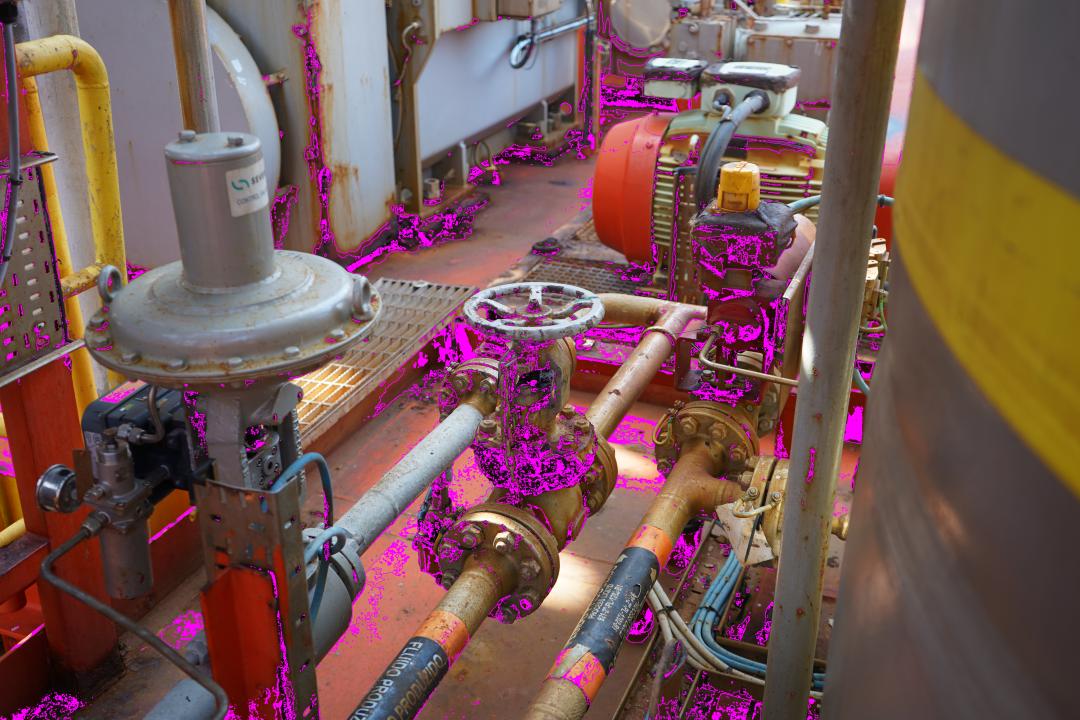

Harpia is a comprehensive corrosion detection and analysis system designed to empower inspectors and analysts. It leverages cutting-edge technologies to:

- Identify and assess corrosive processes in various structures.

- Monitor corrosion evolution for informed decision-making.

- Provide AI-powered decision support for inspectors/analysts.

What is Harpia?

Harpia is an advanced image analysis platform that leverages artificial intelligence, including infrared capabilities, to inspect and assess the condition of large-scale equipment across multiple industries.

Our system excels at detecting and quantifying corrosion, identifying potential equipment failures, and providing actionable insights to prevent costly downtime. By integrating drone technology, Harpia enables safe and efficient inspection of hard-to-reach areas, ensuring comprehensive asset management.

- Inspect large and complex equipment more efficiently

- Eliminate risks associated with inspecting dangerous locations

- Reduce inspection time and cost while improving inspection accuracy and consistency

- Eliminate risks associated with inspecting dangerous locations

How Harpia Works

Harpia leverages advanced robotics and artificial intelligence to deliver unparalleled inspection precision. Our system employs autonomous platforms equipped with a suite of sensors to capture comprehensive data from structures. This data is then processed through powerful AI algorithms to identify anomalies, assess conditions, and generate actionable insights. Harpia’s adaptable design allows for integration with various robotic platforms, ensuring flexibility across diverse inspection environments.

-

Autonomous Data Acquisition

Robotic platforms equipped with cutting-edge sensors collect high-resolution data from target structures.

-

AI-Driven Analysis

Advanced algorithms process vast amounts of data to detect anomalies, assess corrosion, and predict potential failures.

-

Actionable Insights

Harpia provides clear and actionable recommendations to optimize maintenance and extend asset lifespan.

-

Platform Adaptability

Designed for integration with various robotic platforms, ensuring versatility across diverse inspection challenges.

-

Data Security and Privacy

Harpia prioritizes data security and privacy, ensuring the protection of sensitive information throughout the inspection process.

How Does Harpia Work?

The system employs robotic platforms equipped with an array of sensors to thoroughly scan structures. These sensors collect data across different spectrums, enabling the detection of corrosion based on its inherent properties. Currently, the system utilizes aerial drones, but it’s designed to be adaptable to any type of remotely controlled inspection platform.

-

Data Collection

Robotic platforms equipped with various sensors meticulously scan the target structure. This not only identifies potential corrosion but also facilitates 3D modeling for precise analysis. -

AI-powered Analysis

The massive amount of collected data is processed by advanced Computer Vision (CV) and AI algorithms. These algorithms extract key information, eliminating the need for manual analysis and reducing workload for inspectors. -

Integrated Back-end System

A robust back-end system acts as the brain of Harpia. It manages user interfaces, data storage, and business logic, delivering actionable insights to optimize operations.

How Does Harpia Work?

The system employs robotic platforms equipped with an array of sensors to thoroughly scan structures. These sensors collect data across different spectrums, enabling the detection of corrosion based on its inherent properties. Currently, the system utilizes aerial drones, but it’s designed to be adaptable to any type of remotely controlled inspection platform.

-

Data Collection

Robotic platforms equipped with various sensors meticulously scan the target structure. This not only identifies potential corrosion but also facilitates 3D modeling for precise analysis. -

AI-powered Analysis

The massive amount of collected data is processed by advanced Computer Vision (CV) and AI algorithms. These algorithms extract key information, eliminating the need for manual analysis and reducing workload for inspectors. -

Integrated Back-end System

A robust back-end system acts as the brain of Harpia. It manages user interfaces, data storage, and business logic, delivering actionable insights to optimize operations.

How Does Harpia Work?

Harpia leverages advanced robotics and artificial intelligence to deliver unparalleled inspection precision. Our system employs autonomous platforms equipped with a suite of sensors to capture comprehensive data from structures. This data is then processed through powerful AI algorithms to identify anomalies, assess conditions, and generate actionable insights. Harpia’s adaptable design allows for integration with various robotic platforms, ensuring flexibility across diverse inspection environments.

-

Data Collection

Robotic platforms equipped with various sensors meticulously scan the target structure. This not only identifies potential corrosion but also facilitates 3D modeling for precise analysis. -

AI-powered Analysis

The massive amount of collected data is processed by advanced Computer Vision (CV) and AI algorithms. These algorithms extract key information, eliminating the need for manual analysis and reducing workload for inspectors. -

Integrated Back-end System

A robust back-end system acts as the brain of Harpia. It manages user interfaces, data storage, and business logic, delivering actionable insights to optimize operations.

Benefits of Harpia

Transform Your Inspections with Harpia

Discover how Harpia’s innovative technology can revolutionize your inspection processes. Learn about the key benefits that set Harpia apart and how it can deliver significant value to your operations.

Enhanced Accuracy

Benefit from AI-powered image analysis for precise anomaly detection, classification, and severity assessment, reducing the risk of human error.

Cost Reduction

Optimize inspection costs through efficient data management, reduced downtime and labor requirements, and extended equipment lifespan.

Risk Mitigation

Proactively identify and address anomalies before they escalate into costly failures, safeguarding your assets and personnel.

Informed Decision Making

Access real-time data and actionable insights to make informed decisions about maintenance, repairs, and asset management.

Regulatory Compliance

Ensure adherence to industry standards and regulations with comprehensive documentation and reporting.

Scalability

Easily adapt to changing inspection needs and expand Harpia's capabilities across your operations.

Multifaceted Application

Overcoming Industry Challenges with Harpia

Challenges and Solutions

Harpia is designed to tackle the most pressing issues facing the oil and gas industry today. Discover how our innovative solution addresses these challenges and delivers tangible results.

- Operational Efficiency

- Cost Optimization

- Comprehensive Coverage

- Data-Driven Insights

Starting at

Oil and Gas Industries

Harpia addresses several key challenges faced by the oil and gas industry:

- Reduce risks associated with traditional inspection methods.

- Access hard-to-reach areas effortlessly with robotic platforms.

- Minimize downtime with rapid and efficient inspections.

- Optimize inspection costs with a centralized platform and automated analysis.

- Harpia efficiently covers vast areas, reducing inspection time and manpower needs.

Starting at

Pricing

Project Drivers

Cloud Essentials

- Basic cloud storage & computing

- Standard security protocol

- Access to basic collaboration tool

- Regular data backup and recovery options

- Email and chat support

Starting at

Oil and Gas Industries

The Harpia project addresses several key challenges faced by the oil and gas industry

- Reduce risks associated with traditional inspection methods.

- Access hard-to-reach areas effortlessly with robotic platforms.

- Minimize downtime with rapid and efficient inspections.

- Optimize inspection costs with a centralized platform and automated analysis.

- Harpia efficiently covers vast areas, reducing inspection time and manpower needs.

Starting at

Testimonials

Real Results from Real Clients

Discover how Harpia is transforming industries through the eyes of our satisfied clients. See firsthand how our AI-powered inspection solutions are driving efficiency, safety, and cost savings.

Maintenance Supervisor

"We were impressed by Harpia's ability to detect corrosion in our aging infrastructure. The system's accuracy has allowed us to prioritize maintenance efforts and extend the lifespan of our assets. The drone integration is a huge plus for reaching difficult areas."

Engineering Manager

"Harpia has revolutionized our inspection process. The AI-driven insights have helped us optimize maintenance schedules and reduce operational costs. The system's user-friendly interface makes it easy for our team to utilize the data effectively."

Operations Manager

"Harpia has been a game-changer for our offshore operations. The ability to inspect our rigs efficiently and accurately has significantly reduced downtime and improved safety. The AI-powered analysis has identified potential issues before they escalated into major problems."